Conveyor chains mainly have three structural forms: single plate conveyor chain, double plate conveyor chain and bridge conveyor chain.

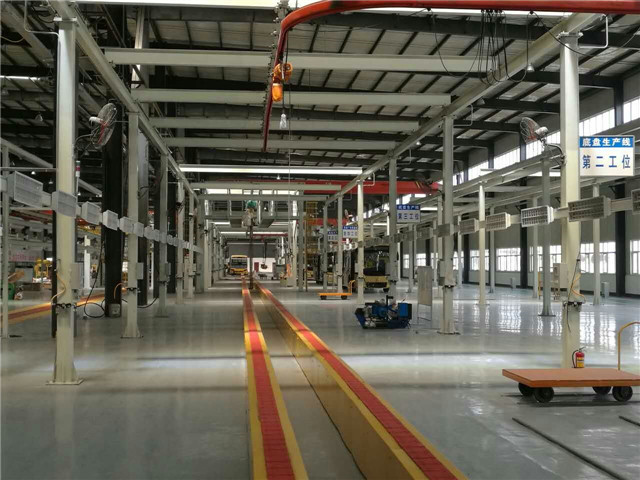

The single-plate chain conveyor line is mainly used for transportation between stations of the passenger car assembly. When working, the single-sided wheel of the passenger car falls on the plate chain, and the plate chain drags the chassis forward to move the station for passenger car assembly. The assembly line is required to meet 6m --For 12m passenger car mixed line production, the assembly line is arranged according to 15 stations, each station is 14m in length, each station has a product load of 12 tons, and the production cycle is 25-50min.

The double-plate chain station conveyor line is mainly used for the station conveying of the bus body welding. When working, the assembled body frame is placed on the plate chain, and the plate chain drags the body forward to move the station and perform the bus welding , The welding conveyor line is arranged in n stations, each station is 8~14m in length, the product load of each station is ≥2 tons, and the production cycle is (2-10) m/min.

The bridge conveyor chain is a special form of the veneer conveyor chain, and the bridge conveyor chain is mainly used for station transportation of the frame line.

中文(簡體)

中文(簡體)